Manual screen changer

Manual screen changer, as the name suggests, is to switch the screen changer directly by manual. The manual screen changer has the advantages of small size and low cost, but its shortcomings are also obvious: the screen changing speed is slow, and it generally needs to stop the machine to change the screen. Due to the consideration of friction resistance and sealing performance, the diameter of its screen is generally less than 100mm.

Hydraulic automatic screen changer

The hydraulic automatic screen changer relies on the hydraulic station with complex structure to switch the screen plate or screen column back and forth. Hydraulic automatic screen changer has the advantages of compact volume, good back pressure sealing, rapid screen changing speed and so on. Its shortcomings are relatively more acceptable: high cost, complex hydraulic structure.

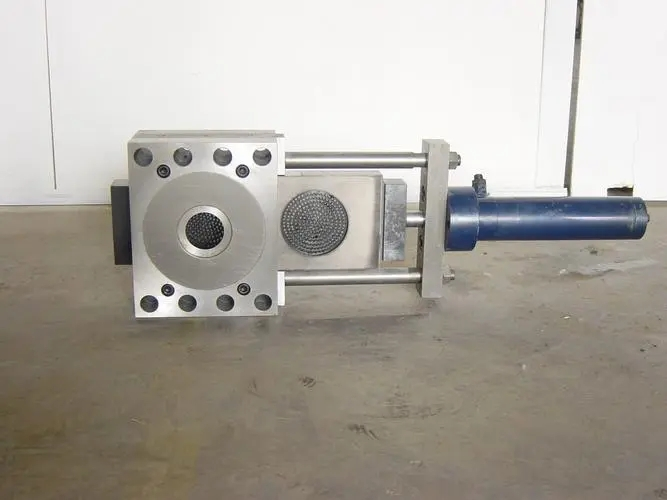

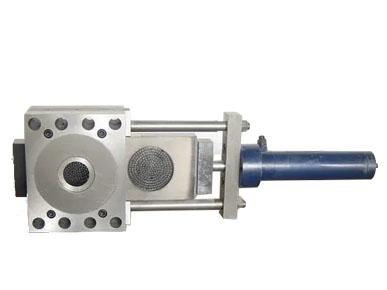

Hydraulic screen changer

Hydraulic screen changer

Mesh belt type automatic mesh filter

This series of filters consists of a 10 meter or 20 meter filter belt, heating and cooling series and electric control system. No additional power is needed, and the screen change is automatically controlled by the pressure activated driving device. There is no fluctuation of material flow and no deformation of products during screen changing. Suitable for: PP, PE, ABS, PS, PMMA and other plastic melts, which are widely used in the production of various films, plates, sheets, high-quality, optical fiber, wiredrawing, granulation and other long process products.