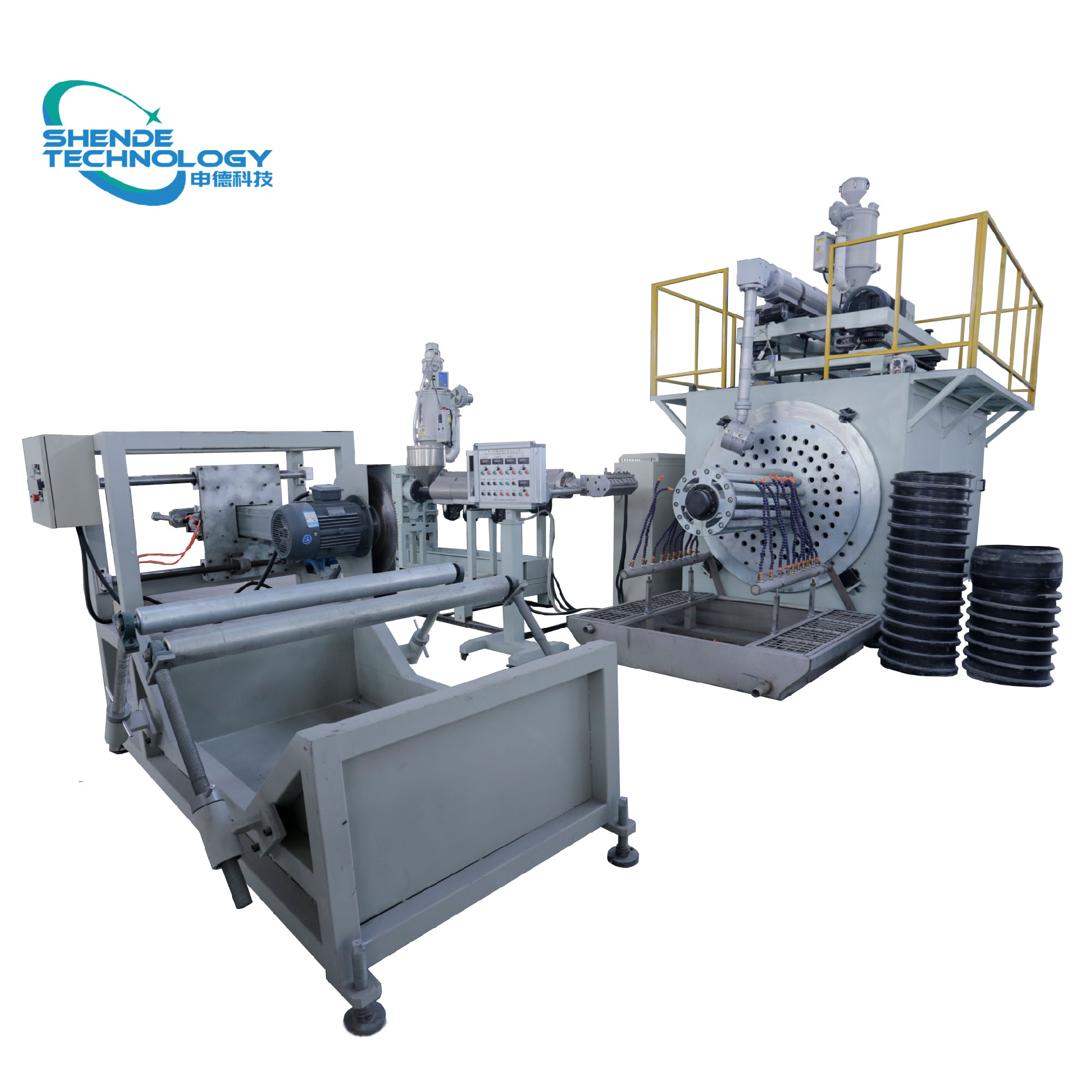

HDPE spiral wound bellows production line is a drainage pipe extrusion production line developed by our company. Production pipe diameter 300~3000 mm. The equipment has the advantages of small investment, advanced production technology, one-time hot-melt molding of inner and outer layers, simple operation and high degree of automation. The inner PE belt and the outer O-shaped pipe are compounded at one time in the molten state. After spray cooling, they will never be layered. The bonding effect of the inner and outer two layers is better than that of the double wall corrugated pipe. The pipe has the advantages of light weight, firm bonding, flared connection, convenient construction and so on. It is mainly used for urban drainage and sewage discharge. The pipe can be used for the production of new PE materials and renewable raw materials.

Technical parameter:

Model 型号 | Pipe Diameter Range 管材范围(mm) | Extruder Model

挤出机型号 | Producing speed of line 生产速度(m/h) | Max. output 最大产量 (kg/h) | Total installed power 装机容量(KVA) | Overall Dimension 外形尺寸 L×W×H |

FLBWG-800 | 300-800 | FSJ-65×33 (2sets) FSJ-40×30 (1sets) | 1-30 | 400 | 170 | 17×8×4.0 |

FLBWG-1200 | 300-1200 | FSJ-75×33 (2sets) FSJ-40×30 (1set) | 1-20 | 800 | 270 | 20×10×4.8 |

FLBWG-2000 | 300-2000 | FSJ-90×33 (2sets) FSJ-50×33 (1set) | 1-18 | 1200 | 350 | 22×12×5 |

FLBW-3000 | 300-3000 | FSJ-100×33 (2sets) FSJ-50×33 (1set) | 1-10 | 1500 | 400 | 25×12×7 |

Inner Diameter 公称内径 (mm) | Ring Stiffness 环刚度 Class S2 S2级 | Weight (Class S2) 米重 (kg/m) | Length 长度 (m) |

300 | ≥8 | 5.6 | 6/12 |

400 | ≥8 | 9.8 | 6/12 |

500 | ≥8 | 12.8 | 6/12 |

600 | ≥8 | 16.8 | 6/12 |

700 | ≥8 | 22.8 | 6/12 |

800 | ≥8 | 26.0 | 6/12 |

900 | ≥8 | 37.0 | 6/12 |

1000 | ≥8 | 49.3 | 6/12 |

1200 | ≥8 | 68.0 | 6/12 |

1500 | ≥8 | 99.0 | 6/12 |

1600 | ≥8 | 118.0 | 6/12 |

1800 | ≥8 | 148.0 | 6/12 |

2000 | ≥8 | 166.0 | 6/12 |

2200 | ≥8 | 200.0 | 6/12 |

2500 | ≥8 | 300.0 | 6/12 |

2800 | ≥8 | 380.0 | 6/12 |

3000 | ≥8 | 450.0 | 6/12 |