PVC edge banding extrusion production line is mainly used to produce all kinds of PVC edge banding, which is widely used in medium and high-grade furniture, kitchenware, bedroom suites, office series, etc.

Applicable material: PVC material

Production process composition of PVC furniture edge banding: raw material mixing ----- plasticization of PVC extrusion host ----- precision die embossing ----- cooling and setting device ----- traction glue passing machine ----- winder

Characteristics of PVC edge banding strip: it has good adhesion, the trimming is the same as the complexion, anti-oxidation, UV protection and other effects, yellowing resistance, oil stain resistance, wear resistance, environmental protection, and no color difference between batches.

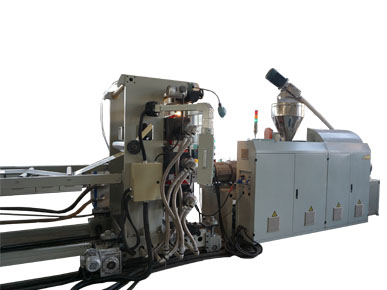

PVC edge banding extrusion line

The edge banding production line is mainly used for all kinds of PVC furniture, door and window edge banding. It is composed of mixer, granulator, single screw extruder, mold, embossing, water tank, traction glue passing machine and winder.

The production process of edge banding strip is as follows

Step 1: color matching raw material mixing granulator granulation.

Step 2: single screw extrusion + mold + embossing + water tank + traction glue passing machine + winder + surface printing.

Or you can directly mix the materials in one step, then eat the powder with twin-screw, and extrude them through a mold