Performance & features:

1. Three layer coextrusion production line:

1.1a extruder: sd150/35 (motor power 132kw)

1.2b extruder: sd80/30 (motor 37KW)

1.3 extrusion output of production line: 900 sheets / day

Eva for plastic machinery:

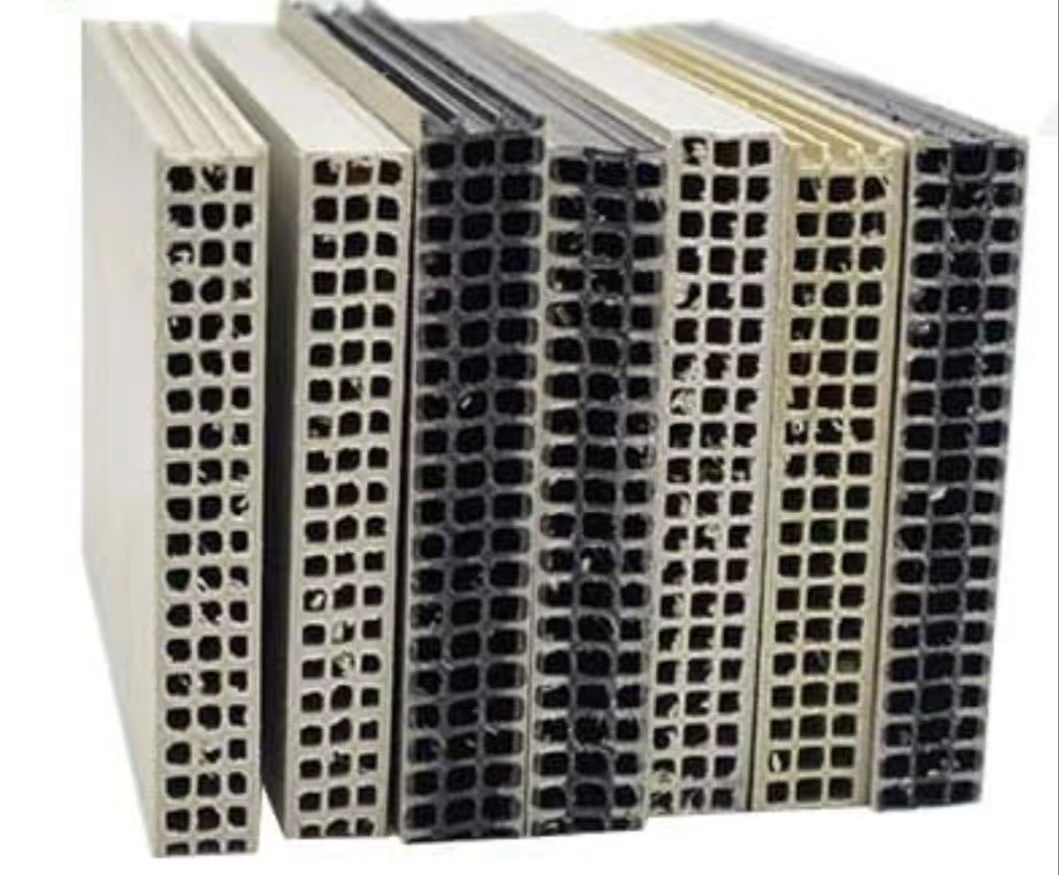

The production line of hollow building formwork is mainly composed of extruder, screen changer, mold, vacuum setting table, tractor, stress eliminator and cutting machine. In the meantime, the extruder is planned to select screws, which includes a temperature control system to ensure excellent plasticization of materials and stable extrusion of high output. PP building formwork production line is widely used in: Transportation Industry: ships, aircraft, passenger cars, train cars, ceilings, car core layer, interior decoration board. Construction and decoration industry: building exterior wall panels, interior decorative panels, residential, office, public space building partitions, commercial decorative shelves, dust-free room panels, ceiling panels, kitchenware, sanitary ware. Advertising: screen printing, computer lettering, advertising signs, display boards, sign boards. Industrial applications: chemical industry anti-corrosion engineering, thermoformed parts, cold storage plate, cold insulation engineering, environmental protection plate. Other uses: formwork, sports equipment, breeding materials, coastal moisture-proof facilities, water-resistant materials, art materials, all kinds of portable partitions.