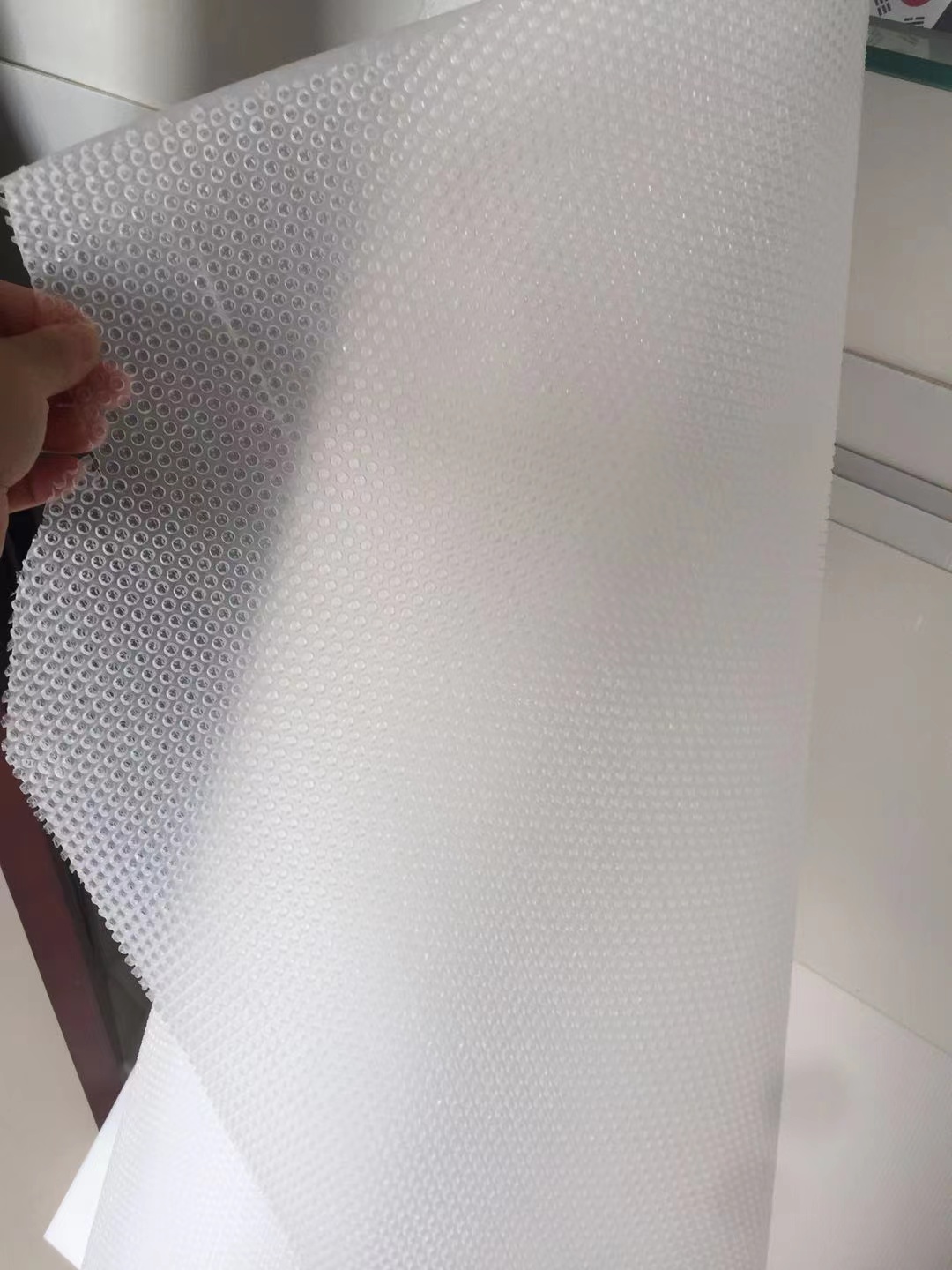

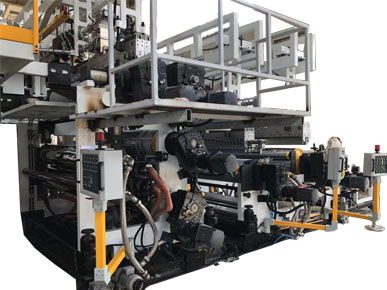

Plastic honeycomb board equipment the honeycomb board produced by PP honeycomb board machine production line is a board made of two thinner panels firmly bonded to both sides of a thick honeycomb core material, also known as honeycomb sandwich structure.

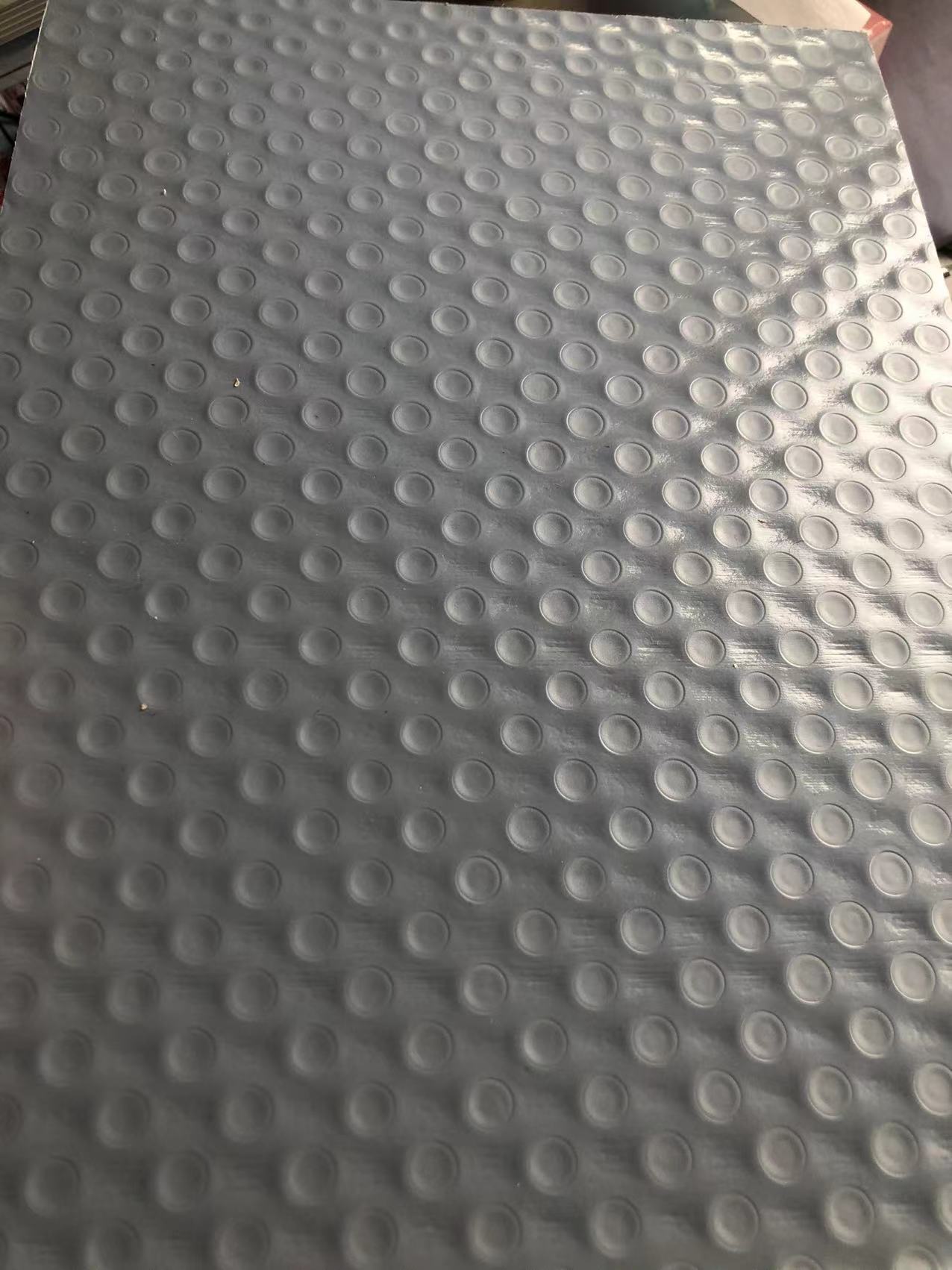

Honeycomb core material is a whole piece of core material with hexagonal and circular hollow (honeycomb) formed by processing and bonding with PC (polycarbonate) and PP (polypropylene). Commonly used panels are PC, PMMA, PETG, etc. The panel must be firmly bonded with the core material with appropriate adhesive to show the excellent characteristics of the honeycomb panel, that is, it has many functions, such as high specific strength, low thermal conductivity and good seismic resistance.

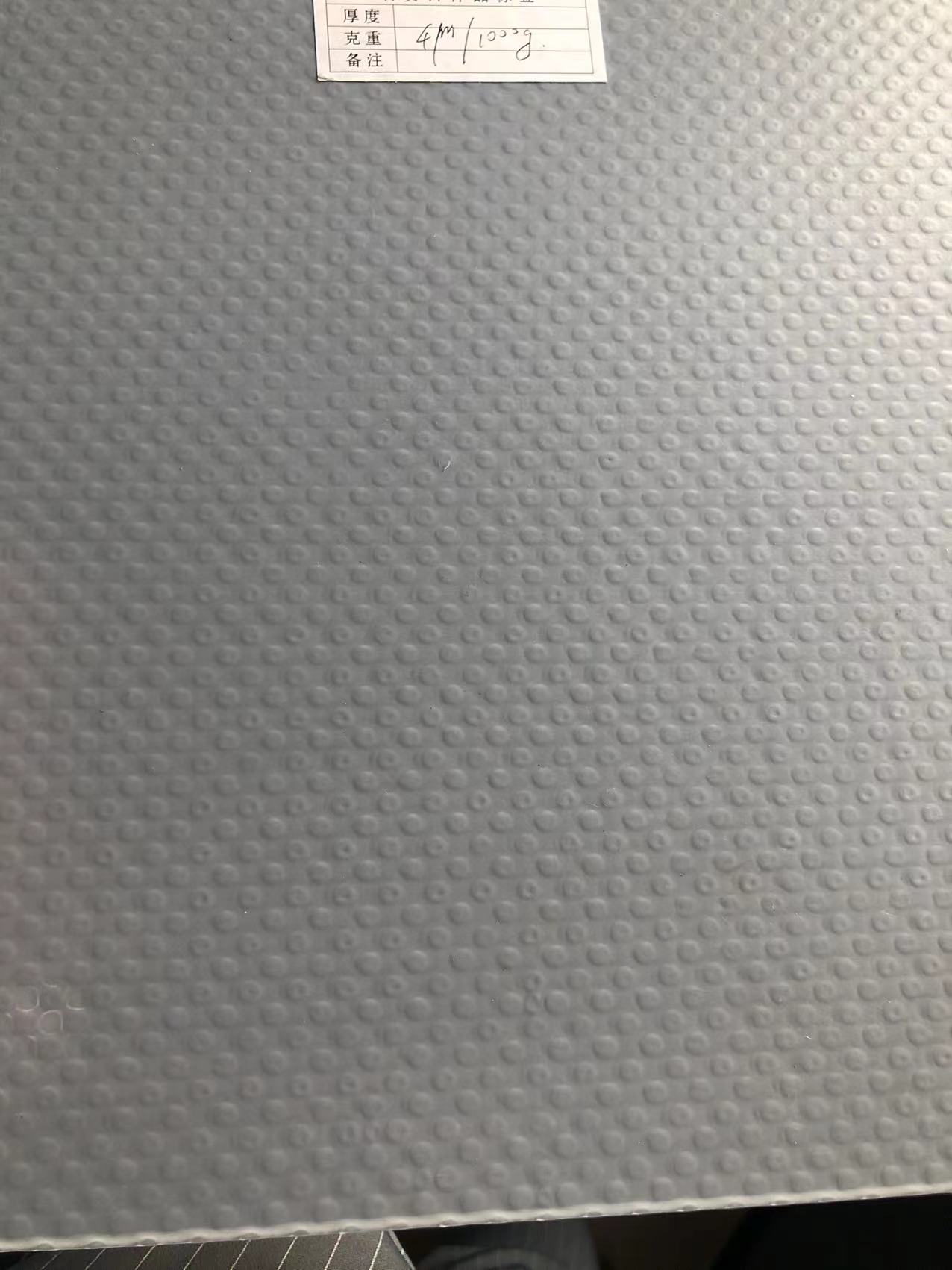

Honeycomb panels are divided into buffer honeycomb panels and packaging honeycomb panels according to their functions. Because of its special structure, it can improve the compressive strength and reduce the cost of plastic honeycomb plate. The hole diameter of honeycomb plate is generally divided into: (round) 6mm, 8mm; (hexagon) 3.6mm, 6mm, 8mm size, PC honeycomb core 8mm:07kg/1m2. Plastic honeycomb panels can be used to make billboards, ceilings, decorative panels, light boxes, etc. Plastic honeycomb panel is a new type of green decorative material which is newly developed this year, saving resources, protecting the ecological environment and low cost. It has many advantages, such as light, strong, stable, thermal insulation and so on.