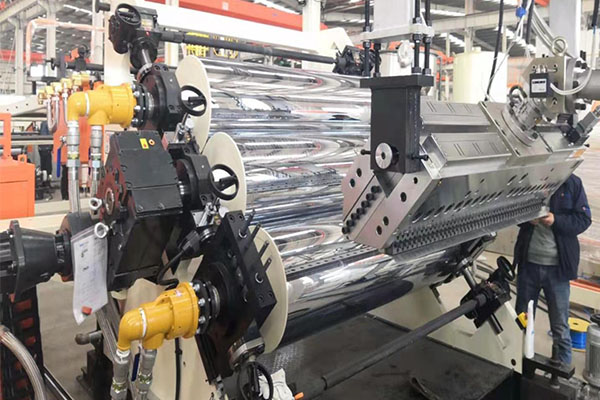

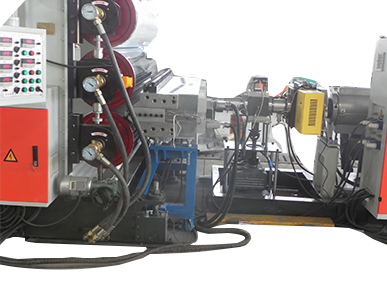

The production line is specially designed for the APET, PET single or multi-layer sheets, it can also produce the PS, PP, PE sheet after change some relative parts. The sheet is used for processing thermoforming or injection products, such as cups, food containers, etc.

PET, APET | PMMA, PC | ||||

Main Extruder Screw Dia | 120mm | 130mm | 75mm(Twin Screw) | 120 | 130 |

Main Extruder Screw L/D | 33:1 | 33:1 | 44:1 | 36:1 | 36:1 |

Main Extruder drive | 160kw | 200kw | 160kw-250kw | 185kw | 250kw |

Co-extruder Screw Dia. | 65mm | 75mm | 65mm or 75mm | 45mm | 45mm |

Co-extruder Screw L/D | 33:1 | 33:1 | 33:1 | 30:1 | 30:1 |

Co-extruder drive | 37kw | 45kw | 37kw or 45kw | 22KW | 22KW |

Sheet Thickness | 0.15mm-1.2mm | 0.8-8mm | 1.5-10mm | ||

Sheet Width | 560mm-1500mm | 1000-1560mm | 1220-2100mm | ||

Max. Extrusion capacity | 350kg/h | 500kg/h | 350kg/h-800kg/h | 420kg/h | 600kg/h |

Installation power | 250kw | 320kw | 200kw-400kw | 180kw | 250kw |